Top 3 Benefits Of Laser Cutting

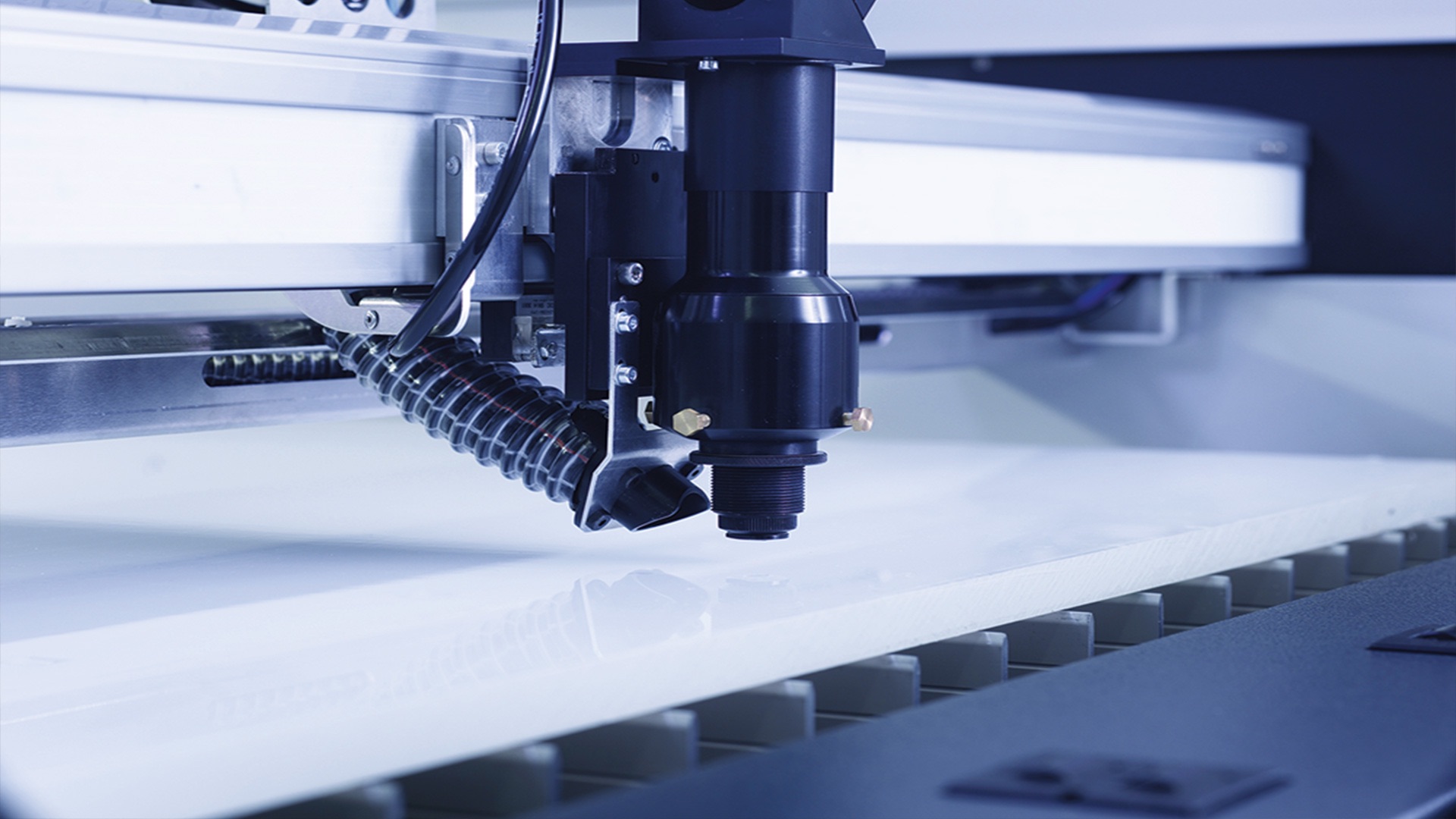

Laser cutting is one of the most powerful manufacturing technologies in use today, and the technology used for laser cutting is advancing at a rapid pace. Today’s modern laser services can cut through a huge variety of materials with extreme precision.

The detail and finish quality of laser cutting is absolutely incredible, and this has made laser cutting very popular among manufacturers who require precision and high quality parts. From aerospace, industrial manufacturers and retail, to companies in the architecture, home building, and interior decorating industries, everyone can benefit from laser cutting

But what are the benefits of laser cutting compared to other methods of fabrication? In this article, we’ll look at the top 3 benefits of laser cutting, to help you understand the best applications of this advanced manufacturing technology.

-

Laser Cutting Offers More Precision Than Traditional Cutting Methods

Manufacturers that use laser services can achieve much higher precision and quality when using laser-based cutting to create components out of a variety of materials. Lasers offer a more consistent, precise cut, compared to traditional manufacturing techniques.

This is because, unlike traditional manufacturing techniques, laser cutting doesn’t require any kind of physical contact with the material being cut. While traditional cutting machines may wear down after excessive use, laser cutting will always provide a high-quality cut and finish.

-

Lower Lead Times, Faster Turnaround

Compared to traditional fabrication methods, laser cutting provides a much lower lead time. Because materials of almost any size, shape, and type can be cut on a single laser cutting machine, there is no need for a long lead time or the setup of multiple machines.

This leads to a much faster turnaround when using laser services. Lasers can also handle large project sizes – at Antech Technologies, our machines can handle material sheets of up to 52” by 100”, in thicknesses of up to 1”.

In addition, smaller order sizes can be delivered more quickly and efficiently, allowing manufacturers to react more quickly to market demand.

-

Capable Of Cutting Materials Of Almost Any Thickness – Without Damage Or Warping

Laser cutting requires no physical contact with the material being cut, and laser machines can be used to achieve incredibly detailed work, even on thin or delicate materials. Because of this, laser cutting is ideal for smaller, more specialized services such as photo engraving.

Laser cutting can be used for dozens of materials and industries, it’s one of the single most versatile methods of material cutting out there – from large parts to delicate, smaller projects, laser cutting offers unparalleled precision and cut quality.

Need Laser Cutting In Toronto? Contact Antech Technologies Today!

If you’re interested in the benefits provided by laser cutting, contact Antech Technologies today! We offer a variety of laser cutting services, and we also offer laser engraving services for a huge variety of materials!

From laser etching to laser cut letters in acrylic, our experienced team can do it all! We can cut materials including:

- Wood such as plywood, balsa wood, and medium-density fiberboard

- Polypropylene, styrene, and polyester

- Acrylic

- Leather, cloth, and textiles

- Laminates (Formica)

- Paper, cardboard, and chipboard

- Rubber

And much more – take a look at our website for further details about our laser cutting services!

We pledge to always provide our customers with the very best laser cutting services, and no job is too big or too small! And we aren’t limited to lasers – we also offer Toronto water jet cutting services, offering our customers powerful metal cutting services for steel and other metals!

So whether you need laser cutting Toronto, waterjet cutting Toronto, Toronto engraving services, or you’re interested in any of the other services we offer, contact us today! We’d be happy to discuss the details of your project, and give you a comprehensive quote!