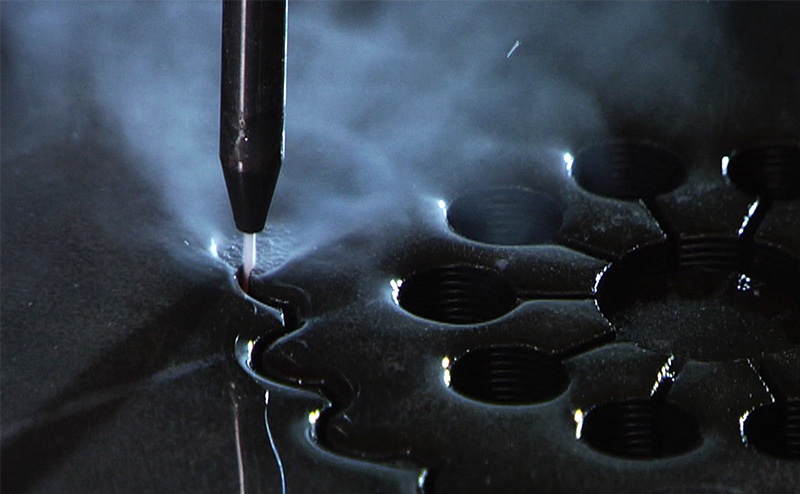

Water Jet Cutting Service

The Antech Technologies difference

In today’s high-tech environment we have heavily invested in state of the art precision water jet cutting machine equipment which gives us a superior advantage in our marketplace.

Waterjet cutting is extremely efficient in creating complex shapes inexpensively and manufacturing forms ready for final use.

Since January 2012 we have been offering precision Waterjet cutting services in the Greater Toronto area. We offer Laser Cutting services with full CAD/CAM capability, same-day quotations, and competitive pricing to all our customers.

Our Flow Water Jet applications overview

We are confident that the relationship with our team at Antech will enable you to deliver the best of Laser Cutting, Laser Engraving & Water jet Cutting technology resources to your clients and partners.

It would also be a good time to revisit our common business opportunities. Together we can find new ways to satisfy your clients’ needs, allowing you to do more in-house business and explore new projects.

WaterJets can cut virtually Any material up to 7″ thick

We can cut letters, panels, parts or artistic projects along with virtually any size and font your customers want.

Now we can cut any shape in aluminum, brass, stainless, composite, copper, stone, glass, ceramic, or any other material. Metal art is no problem for our waterjet cutting services.

Top 3 Benefits Of WaterJet Cutting

Water jet cutting is a fantastic alternative to these traditional CNC options. Using a high-powered stream of water, these machines provide incredibly precise cutting – without many of the disadvantages of other cutting methods. If you need precise craftsmanship with low tolerances, waterjet metal cutting is the best choice for you.

1. No Heat – No Distortion!

Plasma cutters, flame cutters, and laser cutters are all very precise – but due to their design, they heat up the materials that they’re cutting. Depending on the material, this can lead to distortion, melting, and warping of the edges – which is far from ideal when working on a very precise CNC manufacturing project.

Waterjet cutting, on the other hand, does not produce any heat in the affected zone. This means that most waterjets can cut materials to a tolerance of ± 0.005″ – without any heat-induced warping.

2. Able To Cut Virtually Any Material

By adding or reducing the amount of abrasive material in a waterjet cutter, it can be used to cut almost any material.

With pure water, materials like textiles, thin plastics, elastomer, and even food products can be cut using a water jet. When rough abrasive materials are added, water jet cutters can easily cut through hard materials like stone, ceramics, metals, and even bulletproof glass.

This versatility makes waterjet cutting a fantastic choice and provides increased manufacturing flexibility.

3. Creates Less Hazardous Dust

Other cutting methods tend to create dust, grindings, and other hazardous materials. Lasers and plasma cutters, in particular, tend to “vaporize” small amounts of material when cutting, which can lead to some serious environmental hazards.

However, water jet cutting minimizes the risk of these hazards. Harmful dust and chips are carried away with the water – without cutting oils and emulsions required.

This also means that water jet cutting is friendlier to the environment. Because the process results in lower levels of waste, there are fewer dangerous raw materials that must be dumped in landfills.

No Comments

Sorry, the comment form is closed at this time.